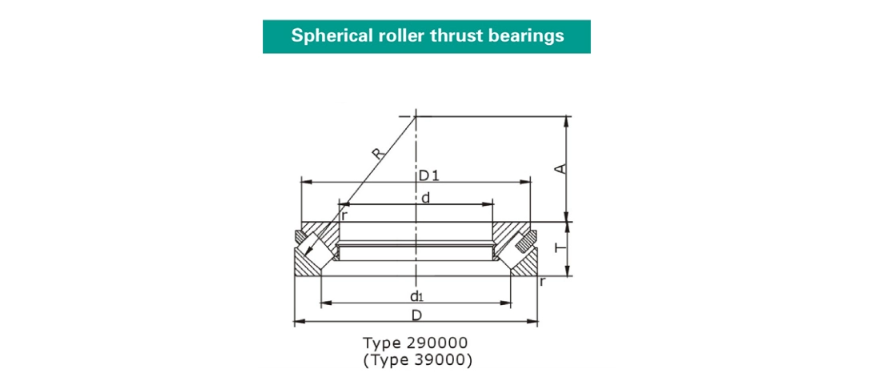

A Spherical Roller Thrust Bearing (SRT) is a heavy-duty bearing designed for very high axial loads, supporting moderate radial loads, and crucially, it self-aligns to accommodate shaft deflection and misalignment between the housing and shaft, making it ideal for harsh conditions in heavy machinery like crushers, gearboxes, and marine propulsion. Its design features spherically shaped rollers within a specially contoured housing washer, allowing it to handle combined heavy thrust and radial forces while maintaining low friction and long life.

Structure Type:Inner and Outer Rings with Rollers: Shaft ring (interference fit with the shaft) + Housing ring (transition fit with the housing) + Spherical roller assembly (including cage), separate design for easy installation and removal, suitable for heavy-duty applications.Roller Arrangement: Spherical rollers are evenly distributed along the spherical raceway of the housing ring. The rollers have a spherical profile, forming point contact with the raceway, automatically compensating for installation eccentricity and shaft deflection (±2°-3°), avoiding localized stress concentration.

Materials:Bearing Rings and Rollers: GCr15 high-carbon chromium steel or SUS440C stainless steel .Cage: Brass , reinforced Nylon 66 , or stamped steel (high rigidity, cost-effective).

Size : Inner diameter (shaft ring) 150–260 mm Outer diameter (housing ring) 215–480 mm Total thickness (shaft ring + housing ring + rollers) 39–132mm

Accuracy: P0 , P6, P5 , P4

Delivery :Standard models 5-12 days;customized models : Please contact the manufacturer.

| Spherical Roller Thrust Bearings | ||||||||||||||||

| Part number | Boundary dimensions | Basic load ratings | Insallation dimersion | Mass | Limiting speeds | |||||||||||

| Currentt | Original | mm | kN | mm | kg | r/min | ||||||||||

| d | d1min | D | D1max | A | T | min | Ca | Coa | damin | Damax | ramax | Currentt | oil | |||

| NB.29230 | 9039230 | 150 | 178 | 215 | 208 | 82 | 39 | 1.5 | 367 | 1440 | 180 | 193 | 1.5 | 4.7 | - | 1800 |

| NB.29330 | 9039330 | 194 | 250 | 240 | 87 | 60 | 2.1 | 777 | 2560 | 195 | 219 | 2 | 11 | 950 | 1400 | |

| NB.29430 | 9039430 | 214 | 300 | 285 | 92 | 90 | 4 | 1449 | 4590 | 220 | 253 | 3 | 28 | 800 | 1100 | |

| NB.29332 | 9039332 | 160 | 208 | 270 | 260 | 92 | 67 | 3 | 910 | 3105 | 210 | 235 | 2.5 | 14.5 | 850 | 1200 |

| NB.29432 | 9039432 | 229 | 320 | 306 | 99 | 95 | 5 | 1610 | 5040 | 235 | 270 | 4 | 33.5 | 750 | 1000 | |

| NB.29334 | 9039334 | 170 | 216 | 280 | 270 | 96 | 67 | 3 | 945 | 3200 | 220 | 245 | 2.5 | 15 | 850 | 1200 |

| NB.29434 | 9039434 | 243 | 340 | 324 | 104 | 103 | 5 | 1820 | 5900 | 250 | 286 | 4 | 44.5 | 700 | 950 | |

| NB.29236 | 9039236 | 180 | 208 | 250 | 243 | 92 | 42 | 1.5 | 445 | 1830 | 215 | 227 | 1.5 | 6.4 | - | 1600 |

| NB.29336 | 9039336 | 232 | 300 | 290 | 103 | 73 | 3 | 1116 | 3870 | 235 | 262 | 2.5 | 19.5 | 800 | 1100 | |

| NB.29436 | 9039436 | 255 | 360 | 342 | 110 | 109 | 5 | 2025 | 6600 | 265 | 304 | 4 | 52.5 | 670 | 900 | |

| NB.29238 | 9039238 | 190 | 226 | 270 | 255 | 103 | 48 | 2 | 518 | 2200 | 225 | 243 | 2 | 8.7 | - | 1400 |

| NB.29338 | 9039338 | 246 | 320 | 308 | 110 | 78 | 4 | 1260 | 4275 | 250 | 280 | 3 | 23.5 | 750 | 1000 | |

| NB.29438 | 9039438 | 271 | 380 | 360 | 117 | 115 | 5 | 2230 | 7200 | 280 | 321 | 4 | 60.5 | 630 | 850 | |

| NB.29240 | 9039240 | 200 | 236 | 280 | 271 | 108 | 48 | 2 | 590 | 2385 | 240 | 254 | 2 | 9.3 | - | 1400 |

| NB.29340 | 9039340 | 261 | 340 | 325 | 116 | 85 | 4 | 1450 | 4950 | 265 | 297 | 3 | 29.5 | 700 | 950 | |

| NB.29440 | 9039440 | 286 | 400 | 380 | 122 | 122 | 5 | 2485 | 8100 | 295 | 337 | 4 | 72 | 600 | 800 | |

| NB.29244 | 9039244 | 220 | 254 | 300 | 292 | 117 | 48 | 2 | 6210 | 2700 | 260 | 273 | 2 | 10 | - | 1300 |

| NB.29344 | 9039344 | 280 | 360 | 345 | 125 | 85 | 4 | 1560 | 5670 | 285 | 316 | 3 | 33.5 | 700 | 950 | |

| NB.29444 | 9039444 | 308 | 420 | 400 | 132 | 122 | 6 | 2590 | 8680 | 315 | 358 | 5 | 75 | 560 | 750 | |

| NB.29248 | 9039248 | 240 | 283 | 340 | 330 | 130 | 60 | 2.1 | 720 | 3100 | 290 | 308 | 2 | 16.5 | - | 1100 |

| NB.29348 | 9039348 | 300 | 380 | 365 | 135 | 85 | 4 | 1610 | 5890 | 135 | 336 | 3 | 35.5 | 670 | 900 | |

| NB.29448 | 9039448 | 326 | 440 | 420 | 142 | 122 | 6 | 2690 | 9180 | 335 | 378 | 5 | 80 | 560 | 750 | |

| NB.29252 | 9039252 | 260 | 302 | 360 | 350 | 139 | 60 | 2.1 | 735 | 3280 | 310 | 326 | 2 | 18.5 | - | 1100 |

| NB.29352 | 9039352 | 329 | 420 | 405 | 148 | 95 | 5 | 1990 | 7470 | 335 | 370 | 4 | 49 | 600 | 800 | |

| NB.29452 | 9039452 | 357 | 480 | 460 | 154 | 132 | 6 | 3160 | 11610 | 365 | 412 | 5 | 105 | 500 | 670 | |

Point contact design + heavy-load reinforced material, leading load-bearing capacity in the industry, adapting to the axial heavy-load requirements of ultra-heavy equipment.

Compensates for ±2°-3° installation deviations and shaft deflection, reducing assembly accuracy requirements and minimizing operational failures.

Split structure facilitates separate installation of shaft washer, housing washer and roller assembly, shortening assembly and maintenance cycles.

Technical specifications fully match imported series, ensuring stable supply and reducing procurement costs by 20%-30%

Compatible with complex heavy-load environments such as dusty, humid, and high-temperature conditions, supports non-standard customization, covering heavy-load needs in multiple industries.

Applications of Spherical Roller Thrust Bearings

1. Heavy-Duty Gearboxes & Speed Reducers

Industrial gear reducers

Marine gearboxes

Wind turbine gearboxes

They support large axial forces generated by helical and bevel gears.

2. Wind Energy Equipment

Wind turbine main shafts

Pitch and yaw systems

Spherical roller thrust bearings handle heavy thrust loads and compensate for structural deflection.

3. Mining & Quarry Equipment

Crushers

Grinding mills

Conveyors

Designed for extreme loads, vibration, and harsh environments.

4. Steel & Metallurgical Machinery

Rolling mills

Continuous casting machines

High load capacity and stiffness are critical in metal processing operations.

5. Construction Machinery

Cranes

Excavators

Slewing mechanisms

They withstand shock loads and axial forces during lifting and rotation.

6. Marine & Offshore Equipment

Propeller shafts

Thrusters

Winches

Used to absorb propeller thrust and heavy axial loads.

7. Pumps & Compressors (Vertical & Heavy Duty)

Vertical pumps

Large compressors

They support the weight of vertical shafts and axial process loads.

8. Oil & Gas Equipment

Drilling rigs

Mud pumps

Offshore platforms

Designed for continuous operation under high thrust loads.

9. Industrial Presses & Extruders

Screw presses

Plastic and rubber extruders

High thrust capacity is essential for axial force transmission.

10. Power Generation Equipment

Hydropower turbines

Steam turbine auxiliary systems

They ensure stable axial load support under heavy operating conditions.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.