A Single Row Cylindrical Roller Bearing is a type of radial bearing using cylindrical rollers for high-capacity radial loads, featuring a single row of rollers between inner and outer rings, often with flanges for some axial guidance, designed for high rigidity, efficiency, and speed in heavy industrial applications like gearboxes and machinery. They are separable (inner and outer rings can mount independently) and come in cage or full-complement designs, with the latter housing more rollers for even heavier loads at lower speeds.

Features:

Inner Ring: Separable or integral structure;

Outer Ring: Separable or integral structure ;

Roller Arrangement: Single row cylindrical rollers;

Accuracy: P0, P6, P5, P4;

Size:

Inner Diameter: 120–1320 mm;

Outer Diameter:180–1600 mm;

Width: 28–345 mm;

Materials:

Bearing Rings & Rollers: GCr15 high-carbon chromium steel or SUS440C stainless steel ;

Cages: Brass , Nylon 66 or stamped steel

Delivery

Standard models: 5–12 days

Customized models :Please contact the manufacturer.

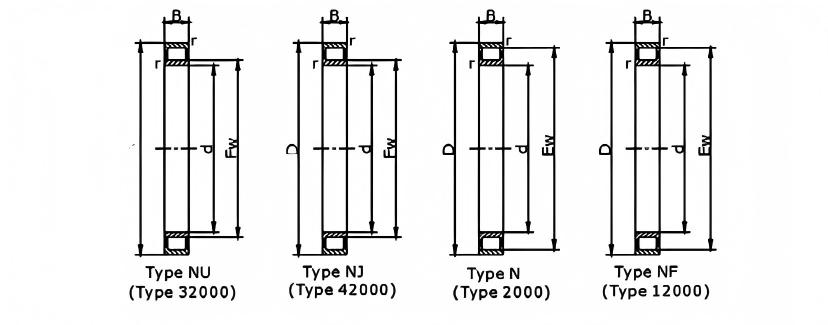

| Part Number | Boundary dimensions | Basic load ratings | Mass | Limiting speeds | ||||||||

| Current | Original | mm | kN | kg | rmin | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| NB.NU 1024M | 32124H | 120 | 180 | 28 | 135 | - | 2 | 130 | 168 | 2.96 | 3400 | 4000 |

| NB.NJ 1024 | 42124 | 180 | 28 | 135 | - | 2 | 130 | 168 | 3.09 | 3400 | 4000 | |

| NB.N 224E | 2224H | 215 | 40 | - | 191.5 | 2.1 | 250 | 211 | 6.2 | 2400 | 3000 | |

| NB.NU 224E | 32224H | 215 | 40 | 143.5 | - | 2.1 | 322 | 422 | 6.2 | 2400 | 3000 | |

| NB.NJ 224E | 42224H | 215 | 40 | 143.5 | - | 2.1 | 322 | 422 | 6.2 | 2400 | 3000 | |

| NB.NJ624 | 42724 | 240 | 80 | 150 | - | 3 | 477 | 408 | 17.8 | 2400 | 3200 | |

| NB.NU 2324E | 32624 | 260 | 86 | 154 | - | 3 | 632 | 868 | 23.8 | 1900 | 2400 | |

| NB.N424 | 2424 | 310 | 72 | - | 260 | 5 | 660 | 530 | 29 | 1900 | 2400 | |

| NB.NU 424 | 32424 | 310 | 72 | 170 | - | 5 | 642 | 772 | 29.1 | 1900 | 2400 | |

| NB.NJ 424 | 42424 | 310 | 72 | 170 | - | 5 | 642 | 772 | 29.1 | 1900 | 2400 | |

| NB.NU 1026 | 32126 | 130 | 200 | 33 | 148 | - | 2 | 152 | 212 | 3.84 | 3200 | 3800 |

| NB.NJ 626 | 42726 | 250 | 80 | 158 | - | 3 | 547 | 473 | 18.7 | 2200 | 3000 | |

| NB.N326E | 2326 | 280 | 58 | - | 243 | 4 | 515 | 410 | 17.8 | 1800 | 2200 | |

| NB.NU 326E | 32326 | 280 | 58 | 167 | - | 4 | 492 | 620 | 17.9 | 1800 | 2200 | |

| NB.NJ 326E | 42326 | 280 | 58 | 167 | - | 4 | 492 | 620 | 18.2 | 1800 | 2200 | |

| NB.N 2326 | 2626 | 280 | 93 | - | 243 | 4 | 770 | 685 | 29 | 1800 | 2200 | |

| NB.NU 2326 | 32626 | 280 | 93 | 167 | - | 4 | 748 | 1060 | 28.7 | 1800 | 2200 | |

| NB.NJ 2326 | 42626 | 280 | 93 | 167 | - | 4 | 748 | 1060 | 29 | 1800 | 2200 | |

| NB.NU 426 | 32426 | 340 | 78 | 185 | - | 5 | 782 | 942 | 41.5 | 1500 | 1900 | |

| NB.NJ 426 | 42426 | 340 | 78 | 185 | - | 5 | 782 | 942 | 41.7 | 1500 | 1900 | |

| NB.N1928 | - | 140 | 190 | 24 | - | 178 | 1.5 | 126 | 190 | 2 | 3200 | 3800 |

| NB.NU1928 | - | 190 | 24 | 154 | - | 1.5 | 126 | 190 | 1.98 | 3200 | 3800 | |

| NB.NU1028 | 32128 | 210 | 33 | 158 | - | 1.1 | 190 | 270 | 3.87 | 2400 | 3000 | |

| NB.NU2228 | - | 250 | 68 | 169 | - | 3 | 500 | 730 | 14.7 | 2000 | 2600 | |

| NB.NJ 2228 | 42528 | 250 | 68 | 169 | - | 3 | 438 | 700 | 17 | 2000 | 2600 | |

| NB.NF 328 | 12328 | 300 | 62 | - | 260 | 4 | 545 | 690 | 21.8 | 1800 | 2200 | |

| Part Number | Boundary dimensions | Basic load ratings | Mass | Limiting speeds | ||||||||

| Current | Original | mm | kN | kg | rmin | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| NB.NU 2938 | 2032938 | 190 | 260 | 42 | 208 | - | 2 | 239 | 216 | 6.45 | 2000 | 2800 |

| NB.NU1038 | 32138 | 290 | 46 | 215 | - | 2.1 | 395 | 595 | 11 | 2000 | 2800 | |

| NB.N238 | 2238 | 340 | 55 | - | 302 | 4 | 630 | 830 | 22.9 | 1600 | 1900 | |

| NB.NU 238 | 32238 | 340 | 55 | 231 | - | 4 | 512 | 745 | 21.6 | 1600 | 1900 | |

| NB.NJ 238 | 42238 | 340 | 55 | 231 | - | 4 | 512 | 745 | 22 | 1600 | 1900 | |

| NB.N2238 | - | 340 | 92 | - | 299 | 4 | 910 | 1400 | 38.6 | 1600 | 1900 | |

| NB.NU 2238 | 32538 | 340 | 92 | 231 | - | 4 | 975 | 1570 | 38.6 | 1600 | 1900 | |

| NB.N 338 | 2338 | 400 | 78 | - | 345 | 5 | 882 | 1190 | 50.2 | 1200 | 1500 | |

| NB.NU 338 | 32338 | 400 | 78 | 245 | - | 5 | 882 | 1190 | 48.5 | 1200 | 1500 | |

| NB.N 1040 | 42140 | 200 | 310 | 51 | - | 281 | 2 | 408 | 408 | 10.2 | 1900 | 2400 |

| NB.NU 1040 | 32140 | 310 | 51 | 229 | - | 2.1 | 408 | 615 | 14.3 | 1900 | 2400 | |

| NB.NJ 1040 | 42140 | 310 | 51 | 229 | - | 2.1 | 408 | 615 | 14.7 | 1900 | 2400 | |

| NB.NU2040 | - | 310 | 66 | 229 | - | 3 | 560 | 925 | 18.5 | 1900 | 2400 | |

| NB.N240 | 2240 | 360 | 58 | - | 316 | 4 | 570 | 842 | 26.8 | 1500 | 1800 | |

| NB.NU 240 | 32240 | 360 | 58 | 244 | - | 4 | 570 | 842 | 26.5 | 1500 | 1800 | |

| NB.NJ 240 | 42240 | 360 | 58 | 244 | - | 4 | 570 | 842 | 27.1 | 1500 | 1800 | |

| NB.N2340 | 2640 | 420 | 138 | - | 360 | 4 | 1510 | 2240 | 94.5 | 1200 | 1500 | |

| NB.NU 3340 | 3032340 | 420 | 165 | 260 | - | 5 | 1730 | 2660 | 118 | 1200 | 1500 | |

| NB.NU 1044 | 32144 | 220 | 340 | 56 | 250 | - | 3 | 448 | 685 | 19.3 | 1800 | 2200 |

| NB.NJ 1044 | 42144 | 340 | 56 | 250 | - | 3 | 448 | 685 | 19.6 | 1800 | 2200 | |

| NB.N244 | 2244 | 400 | 65 | - | 350 | 4 | 702 | 1050 | 36.7 | 1500 | 1800 | |

| NB.NU 244 | 32244 | 400 | 65 | 270 | - | 4 | 702 | 1050 | 35 | 1500 | 1800 | |

| NB.NJ 244 | 42244 | 400 | 65 | 270 | - | 4 | 702 | 1050 | 35.4 | 1500 | 1800 | |

| NB.NU 2244 | 32544 | 400 | 108 | 259 | - | 4 | 1360 | 2330 | 62.2 | 1300 | 1600 | |

| NB.NJ 2244 | 42544 | 400 | 108 | 270 | - | 4 | 1360 | 2330 | 62.2 | 1300 | 1600 | |

| NB.NU 344 | 32344 | 460 | 88 | 284 | - | 5 | 1080 | 1465 | 75.6 | 1200 | 1500 | |

| Part Number | Boundary dimensions | Basic load ratings | Mass | Limiting speeds | ||||||||

| Current | Original | mm | kN | kg | rmin | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| NB.NU 2344 | 32644 | 220 | 460 | 145 | 284 | - | 5 | 1780 | 2620 | 114 | 1000 | 1300 |

| NB.NF 646 | 402746 | 230 | 350 | 70 | - | 316 | 2.1 | 856 | 610 | 26 | 1500 | 1900 |

| NB.N646 | 2746 | 370 | 80 | - | 334 | 3 | 826 | 795 | 37 | 1400 | 1800 | |

| NB.N0048 | 7002148 | 240 | 360 | 37 | - | 325 | 2.1 | 388 | 392 | 14.7 | 1000 | 1400 |

| NB.NU 1048 | 32148 | 360 | 56 | 270 | - | 3 | 470 | 745 | 20.4 | 1700 | 2000 | |

| NB.NJ 1048 | 42148 | 360 | 56 | 270 | - | 3 | 470 | 745 | 21 | 1700 | 2000 | |

| NB.NU 3248 | 3032148 | 360 | 92 | 270 | - | 3 | 855 | 938 | 35.5 | 1000 | 1300 | |

| NB.NU1148 | - | 400 | 74 | 282 | - | 4 | 975 | 1500 | 39.1 | 1300 | 1600 | |

| NB.N248 | 2248 | 440 | 72 | - | 395 | 4 | 1100 | 1550 | 50.3 | 1300 | 1600 | |

| NB.NU 248 | 32248 | 440 | 72 | 295 | - | 4 | 880 | 1345 | 46.9 | 1300 | 1600 | |

| NB.NJ 248 | 42248 | 440 | 72 | 295 | - | 4 | 880 | 1345 | 49.6 | 1300 | 1600 | |

| NB.NU2248E | - | 440 | 120 | 295 | - | 4 | 1700 | 2500 | 84.1 | 1200 | 1500 | |

| NB.NU 348 | 32348 | 500 | 95 | 310 | - | 5 | 1290 | 1810 | 97.7 | 1000 | 1300 | |

| NB.NU2348 | - | 500 | 155 | 310 | - | 5 | 2000 | 2900 | 150 | 1000 | 1300 | |

| NB.N650 | 2750 | 250 | 380 | 50 | - | 347 | 4 | 660 | 643 | 19.8 | 1300 | 1700 |

| NB.N0052 | 7002152 | 260 | 400 | 44 | - | 360 | 3 | 552 | 603 | 22.7 | 1500 | 1800 |

| NB.N 1052 | 2152 | 400 | 65 | - | 364 | 4 | 621 | 630 | 30.8 | 1500 | 1800 | |

| NB.NU 1052 | 32152 | 400 | 65 | 296 | - | 4 | 592 | 932 | 29.5 | 1500 | 1800 | |

| NB.NU3152E | - | 440 | 144 | 298.5 | - | 4 | 2300 | 3500 | 92.9 | 1200 | 1500 | |

| NB.NU 252 | 32252 | 480 | 80 | 320 | - | 5 | 1100 | 1580 | 67.2 | 1100 | 1400 | |

| NB.NJ1856 | - | 280 | 350 | 33 | 299 | - | 2.1 | 210 | 440 | 7.31 | 1500 | 1800 |

| NB.N1856X3 | - | 360 | 30 | - | 339 | 4 | 325 | 605 | 7.76 | 1400 | 1700 | |

| NB.N1956 | - | 380 | 46 | - | 354 | 2.1 | 495 | 875 | 15.3 | 1400 | 1700 | |

| NB.NU1956 | - | 380 | 46 | 306 | - | 3 | 450 | 785 | 14.5 | 1400 | 1700 | |

| NB.N1056 | 2156 | 420 | 65 | - | 384 | 4 | 840 | 1500 | 33 | 1400 | 1700 | |

| NB.NU2056 | - | 420 | 82 | 316 | - | 4 | 1050 | 1900 | 41.8 | 1400 | 1700 | |

| NB.NU 1056 | 32156 | 420 | 65 | 316 | - | 4 | 600 | 965 | 33.4 | 1400 | 1700 | |

| Part Number | Boundary dimensions | Basic load ratings | Mass | Limiting speeds | ||||||||

| Current | Original | mm | kN | kg | rmin | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| NB.NU1960MA | - | 300 | 420 | 56 | 332 | - | 3 | 500 | 850 | 23.4 | 1200 | 1500 |

| NB.NU 1060 | 32160 | 460 | 74 | 340 | - | 4 | 880 | 1470 | 44.4 | 1200 | 1500 | |

| NB.NJ 1060 | 42160 | 460 | 74 | 340 | - | 4 | 880 | 1470 | 45.1 | 1200 | 1500 | |

| NB.NU 3060 | 3032160 | 460 | 118 | 340 | - | 4 | 1690 | 1340 | 72 | 1060 | 1340 | |

| NB.NU3160 | - | 500 | 160 | 358 | - | 5 | 2000 | 4000 | 135 | 1000 | 1300 | |

| NB.NU 260 | 32260 | 540 | 85 | 364 | - | 5 | 1350 | 1290 | 87.2 | 1000 | 1300 | |

| NB.NU 360 | 32360 | 620 | 109 | 385 | - | 7.5 | 2010 | 1840 | 166 | 900 | 1100 | |

| NB.N1864 | - | 320 | 400 | 38 | - | 380 | 2.1 | 340 | 680 | 10.7 | 1100 | 1400 |

| NB.N2964M | - | 440 | 72 | - | 408 | 3 | 735 | 1520 | 33.7 | 1200 | 1500 | |

| NB.NU 1064 | 32164 | 480 | 74 | 360 | - | 4 | 890 | 1520 | 47 | 1100 | 1400 | |

| NB.NJ 1064 | 42164 | 480 | 74 | 360 | - | 4 | 890 | 1520 | 47 | 1100 | 1400 | |

| NB.NU2064 | - | 480 | 95 | 360 | - | 4 | 1540 | 2800 | 61 | 1100 | 1400 | |

| NB.N0068 | 7002168 | 340 | 520 | 57 | - | 470 | 4 | 995 | 935 | 45.5 | 950 | 1200 |

| NB.NU1068 | 32168 | 520 | 82 | 385 | - | 5 | 1200 | 2000 | 62.6 | 955 | 1200 | |

| NB.NU2068 | - | 520 | 106 | 385 | - | 5 | 1950 | 3730 | 84.6 | 955 | 1200 | |

| NB.N668 | 2768 | 530 | 133.5 | - | 476 | 4 | 1660 | 1810 | 117 | 880 | 1100 | |

| NB.NU1072 | 32172 | 360 | 540 | 82 | 405 | - | 5 | 1200 | 2050 | 65.6 | 900 | 1100 |

| NB.NU 2272 | 32572 | 650 | 170 | 435 | - | 6 | 3500 | 6050 | 263 | 850 | 1000 | |

| NB.NU 2372 | 32672 | 750 | 224 | 465 | - | 7.5 | 5010 | 8740 | 485 | 850 | 1000 | |

| NB.N2876 | 2002876 | 380 | 480 | 60 | - | 451 | 2.1 | 647 | 756 | 24.6 | 900 | 1100 |

| NB.NU1076 | 32176 | 560 | 82 | 425 | - | 5 | 1250 | 2150 | 68.5 | 900 | 1100 | |

| NB.NU2276 | - | 680 | 177 | 451 | - | 6 | 3860 | 6410 | 282 | 700 | 900 | |

| NB.NU 1980 | 1032980 | 400 | 540 | 65 | 438 | - | 4 | 785 | 988 | 42.7 | 950 | 1150 |

| NB.NU 1080 | 32180 | 600 | 90 | 450 | - | 5 | 1420 | 2480 | 88.8 | 900 | 1100 | |

| NB.N3080 | - | 600 | 148 | - | 554 | 5 | 2400 | 4400 | 151 | 700 | 900 | |

| NB.NU 3080 | 3032180 | 600 | 148 | 458 | - | 5 | 2150 | 4450 | 145 | 700 | 900 | |

| NB.N2180 | 2002780 | 650 | 145 | - | 585 | 6 | 2830 | 3030 | 190 | 700 | 900 | |

| Part Number | Boundary dimensions | Basic load ratings | Mass | Limiting speeds | ||||||||

| Current | Original | mm | kN | kg | rmin | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| NB.NU1084 | 32184 | 420 | 620 | 90 | 470 | - | 5 | - | - | - | 700 | 900 |

| NB.NU 688 | 32788 | 440 | 546 | 46 | 468 | - | 2.5 | 413 | 476 | 26.5 | 730 | 920 |

| NB.NU1088 | 32188 | 650 | 94 | 493 | - | 6 | 1600 | 2850 | 106 | 700 | 900 | |

| NB.N 1188 | 1002788 | 720 | 122 | - | 648 | 6 | 2320 | 2220 | 191 | 510 | 620 | |

| NB.N 2992 | 2002992 | 460 | 620 | 95 | - | 580 | 4 | 1340 | 2930 | 82.4 | 500 | 630 |

| NB.NU 2992 | 2032992 | 620 | 95 | 504 | - | 4 | 1340 | 2060 | 84 | 500 | 630 | |

| NB.NU3192 | - | 760 | 240 | 529.3 | - | 7.5 | 5210 | 9690 | 419 | 400 | 500 | |

| NB.NU 29/500 | 20329/500 | 500 | 670 | 100 | 543 | - | 5 | 2000 | 2410 | 99.5 | 560 | 710 |

| NB.NU10/500 | - | 720 | 100 | 556 | - | 6 | 2050 | 3710 | 137 | 400 | 500 | |

| NB.NU 29/530 | 20329/530 | 530 | 710 | 106 | 578 | - | 5 | 1770 | 3900 | 123 | 400 | 500 |

| NB.NU10/560 | - | 560 | 820 | 115 | 625 | - | 6 | 2550 | 4700 | 205 | 380 | 460 |

| NB.NU18/600 | - | 600 | 730 | 60 | 635 | - | 3 | 830 | 1950 | 49.2 | 400 | 500 |

| NB.N19/600 | - | 800 | 90 | - | 750 | 5 | 1210 | 2140 | 115 | 380 | 460 | |

| NB.NU19/600 | - | 800 | 90 | 649 | - | 5 | 1950 | 2650 | 122 | 380 | 460 | |

| NB.NUP29/600 | - | 800 | 118 | 650 | - | 5 | 2430 | 5110 | 173 | 380 | 460 | |

| NB.NU 19/630 | 10329/630 | 630 | 850 | 100 | 688 | - | 6 | 1850 | 3900 | 160 | 280 | 360 |

| NB.NU 29/630 | 20329/630 | 850 | 128 | 685 | - | 6 | 3050 | 4260 | 206 | 280 | 360 | |

| NB.NJ18/670 | - | 670 | 820 | 69 | 708 | - | 4 | 1230 | 2830 | 78.4 | 280 | 360 |

| NB.NU 6/700 | 327/700 | 700 | 930 | 160 | 760 | - | 6 | 3200 | 4580 | 295 | 310 | 390 |

| NB.NJ18/710 | - | 710 | 870 | 74 | 750 | - | 4 | 1300 | 3000 | 94.5 | 310 | 390 |

| NB.N 19/710 | 10023/710 | 950 | 106 | - | 890 | 6 | 2300 | 5000 | 205 | 220 | 300 | |

| NB.NU 19/710 | 10329/710 | 950 | 106 | 775 | - | 6 | 2300 | 5000 | 207 | 220 | 300 | |

| NB.NU 19/800 | 10329/800 | 800 | 1060 | 115 | 870 | - | 6 | 2760 | 6150 | 280 | 200 | 240 |

| NB.N 6/840 | 27/840 | 840 | 1040 | 125 | - | 985 | 3 | 2530 | 5290 | 240 | 200 | 240 |

| NB.NU 19/850 | 10329/850 | 850 | 1120 | 118 | 925 | - | 6 | 2780 | 6350 | 320 | 170 | 220 |

| NB.NF19/850 | - | 1120 | 118 | - | 1059 | 6 | 3318 | 7156 | 282 | 170 | 220 | |

| NB.NU 29/850 | 20329/850 | 1120 | 155 | 917 | - | 6 | 4450 | 10500 | 425 | 170 | 220 | |

| Part Number | Boundary dimensions | Basic load ratings | Mass | Limiting speeds | ||||||||

| Current | Original | mm | kN | kg | rmin | |||||||

| d | D | B | Fw | Ew | rmin | Cr | Cor | Grease | Oil | |||

| NB.NJ18/870 | - | 870 | 1050 | 90 | 912 | - | 5 | 2140 | 5280 | 152 | 170 | 220 |

| NB.NU18/880 | - | 880 | 950 | 60 | 898 | - | 2.5 | 775 | 2900 | 36.8 | 200 | 240 |

| NB.NUP18/880 | - | 950 | 60 | 898 | - | 2.5 | 800 | 3000 | 39.4 | 200 | 240 | |

| NB.NU 29/950 | 20329/950 | 950 | 1250 | 175 | 1024 | - | 7.5 | 5270 | 9120 | 563 | 140 | 170 |

| NB.N 39/950 | 30029/950 | 1250 | 224 | - | 1170 | 7.5 | 6780 | 10500 | 745 | 140 | 170 | |

| NB.N18/1000 | - | 1000 | 1210 | 92 | - | 1155 | 5 | 1350 | 2760 | 206 | 120 | 150 |

| NB.NU 18/1000 | 10328/1000 | 1220 | 100 | 1053 | - | 6 | 2376 | 5895 | 265 | 120 | 150 | |

| NB.NU28/1000 | - | 1220 | 128 | 1058 | - | 6 | 3200 | 8850 | 319 | 120 | 150 | |

| NB.NF28/1000 | - | 1220 | 128 | - | 1165 | 6 | 3680 | 10020 | 350 | 120 | 150 | |

| NB.NUP 18/1000 | 10928/1000 | 1220 | 128 | 1053 | - | 6 | 2376 | 5896 | 287 | 120 | 150 | |

| NB.NU 29/1000 | 20329/1000 | 1320 | 185 | 1082 | - | 7.5 | 6336 | 15570 | 700 | 110 | 140 | |

| NB.NU38/1060 | - | 1060 | 1280 | 165 | 1120 | - | 6 | 3750 | 11300 | 427 | 120 | 150 |

| NB.N 28/1060 | 20028/1060 | 1280 | 128 | - | 1225 | 6 | 3222 | 9360 | 360 | 110 | 140 | |

| NB.NU 19/1060 | 10329/1060 | 1400 | 150 | 1162 | - | 7.5 | 4500 | 10000 | 683 | 120 | 150 | |

| NB.NU 29/1060 | 20329/1060 | 1400 | 195 | 1142 | - | 7.5 | 6489 | 15570 | 870 | 120 | 150 | |

| NB.NU 39/1060 | 30329/1060 | 1400 | 250 | 1146 | - | 7.5 | 8217 | 21600 | 1070 | 120 | 150 | |

| NB.N 30/1060 | 30021/1060 | 1500 | 325 | - | 1390 | 9.5 | 11700 | 29250 | 1900 | - | - | |

| NB.NJ 18/1120 | 10428/1120 | 1120 | 1360 | 106 | 1182 | - | 6 | 3069 | 7785 | 335 | - | - |

| NB.NU38/1120 | - | 1360 | 180 | 1180 | - | 6 | 5700 | 17300 | 547 | - | - | |

| NB.NU 30/1120 | 30321/1120 | 1580 | 345 | 1231 | - | 9.5 | 14130 | 35100 | 2150 | - | - | |

| NB.NU18/1180 | - | 1180 | 1420 | 106 | 1245 | - | 6 | 3250 | 8500 | 328 | - | - |

| NB.NJ 18/1180 | 10428/1180 | 1420 | 106 | 1245 | - | 6 | 2727 | 7020 | 350 | - | - | |

| NB.NU 29/1180 | 20329/1180 | 1540 | 206 | 1258 | - | 7.5 | 8073 | 19440 | 1050 | - | - | |

| NB.N 39/1180 | 30029/1180 | 1540 | 272 | - | 1466 | 7.5 | 10080 | 26100 | 1400 | - | - | |

| NB.N 20/1250 | 20021/1250 | 1250 | 1750 | 290 | - | 1635 | 9.5 | 11520 | 27450 | 2320 | - | - |

| NB.NU19/1250 | - | 1630 | 170 | 1350 | - | 7.5 | 6300 | 15400 | 952 | - | - | |

| NB.NU 18/1320 | 10328/1320 | 1320 | 1600 | 122 | 1395 | - | 6 | 34200 | 9000 | 530 | - | - |

Line contact design + optimized roller layout, leading radial load-bearing capacity in the industry, adapting to the needs of heavy-load and ultra-heavy-load equipment.

Separable structure eliminates the need to disassemble related components, installation, replacement and maintenance efficiency increased by more than 50%, reducing labor costs.

P4-class ultra-precision + strong deformation resistance, ensuring micron-level equipment operation accuracy and reducing operation errors.

Technical specifications fully match those of imported series, ensuring stable supply and reducing procurement costs by 20%-30%.

Compatible with various environments such as clean, high-temperature, humid, and dusty conditions, supports non-standard customization, and adapts to multiple fields such as industrial machinery, machine tools, and motors.

1. Electric Motors & Generators

Industrial electric motors

Traction motors

Large generators

They support heavy rotor loads while allowing high-speed operation.

2. Gearboxes & Speed Reducers

Industrial gearboxes

Wind turbine gear units

Conveyor drive systems

Single row cylindrical roller bearings handle large gear forces and maintain accurate shaft alignment.

3. Machine Tools

Spindles of lathes, mills, and grinders

Feed mechanisms

They provide high radial stiffness essential for machining accuracy.

4. Pumps & Compressors

Centrifugal pumps

Screw compressors

Turbo compressors

The bearings maintain shaft stability under continuous radial loading.

5. Steel & Metallurgical Machinery

Rolling mills

Continuous casting machines

Steel processing lines

These applications demand bearings capable of handling very high radial loads and shock loads.

6. Wind Energy Equipment

Wind turbine gearboxes

Generator shafts

They withstand heavy loads and vibration in long-life applications.

7. Construction & Mining Equipment

Crushers

Conveyors

Excavators

Single row cylindrical roller bearings provide robustness in harsh environments.

8. Paper, Printing & Textile Machinery

Paper machine rollers

Printing press cylinders

Textile processing machines

They support long rollers with high radial loads and smooth rotation.

9. Railway & Transportation

Traction motors

Axle gear units

Designed for high reliability under heavy loads and vibration.

10. Industrial Fans & Blowers

Large ventilation fans

Industrial blowers

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.