✅ Meets Your Design Requirements

Bearing rings: Carburized steel G20CrNi2MoA (surface hardness HRC 60-62)

Rolling elements: Ceramic ZrO₂ (insulating and antimagnetic) or bearing steel GCr15

Cages: PEEK composite material (high temperature resistance up to 120℃)

✅ Wide Range of Sizes & Precision Grades

Inner diameter range: 15mm–200mm

Outer diameter range: 24mm–220mm

Cross-section height: 3mm–5mm

Precision grades:

P4 (standard grade): Runout ≤ 0.0015mm

SP4 (ultra-precision grade): Runout ≤ 0.001mm

✅ Delivery Time

Standard models: Shipped within 5-10 days

Customized models: 3-5 weeks

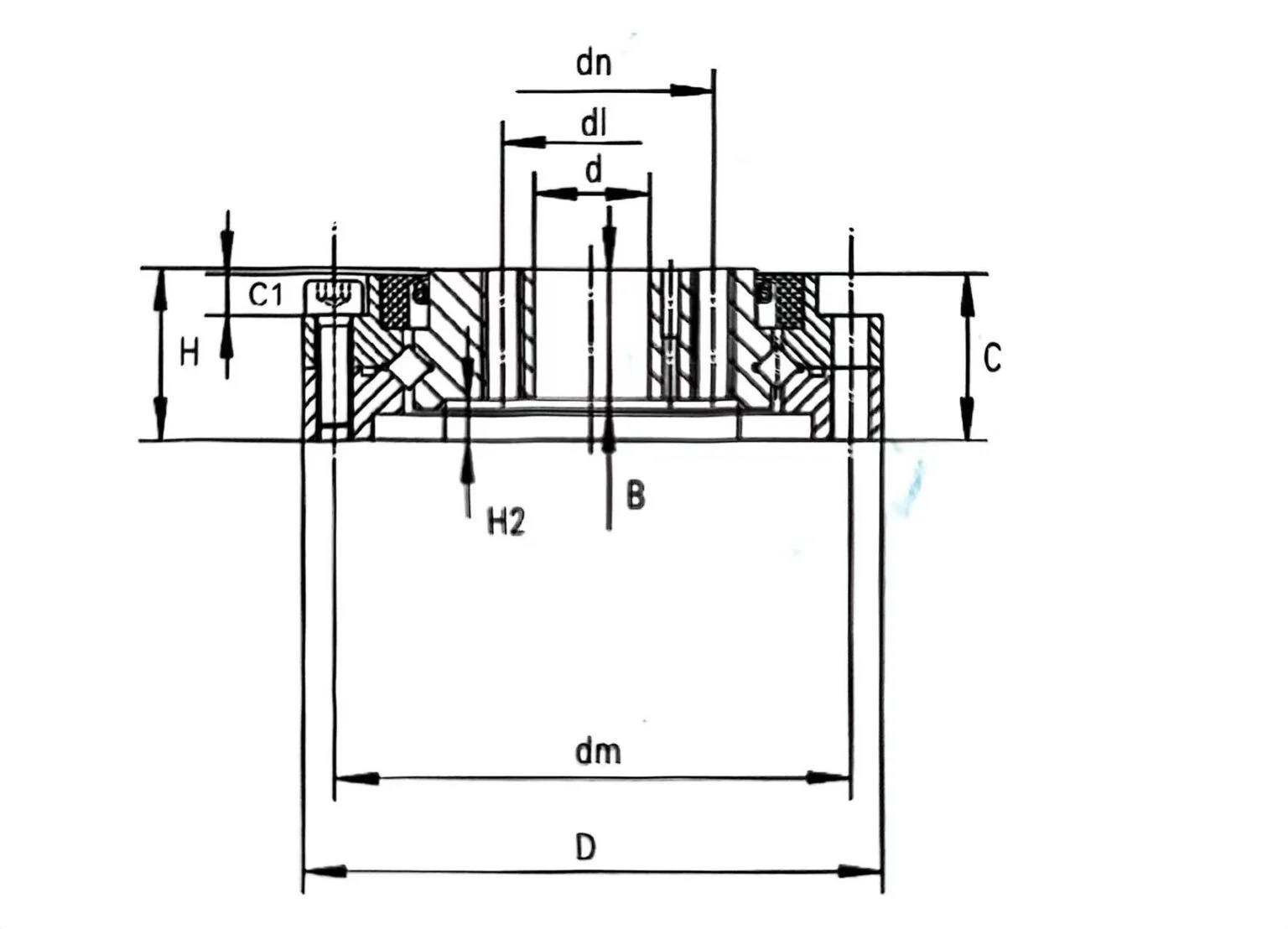

| CSF Harmonic Reducer Bearing | ||||||||||||

| Bearing type | D | d | C | H | B | dm | dm | dn | dn | dl | dl | weight |

| CSF(G)-14 | 55 | 11 | 16 | 16.5 | 13.5 | 49 | 8-φ3.5 | 23 | 6-M4 | 17 | 6-M4 | 0.35 |

| CSF(G)-17 | 62 | 10 | 16 | 16.5 | 13.5 | 56 | 10-φ3.5 | 27 | 6-M5 | 19 | 6-M5 | 0.4 |

| CSF(G)-20 | 70 | 14 | 16 | 16.5 | 13.5 | 64 | 12-φ3.5 | 32 | 8-M6 | 24 | 8-M5 | 0.5 |

| CSF(G)-25 | 85 | 20 | 18 | 18.5 | 16.5 | 79 | 16-φ3.5 | 42 | 8-M8 | 30 | 8-M6 | 0.72 |

| CSF(G)-32 | 112 | 26 | 21.5 | 22.5 | 19 | 104 | 16-φ4.5 | 55 | 8-M10 | 40 | 8-M8 | 1.74 |

| CSF(G)-40 | 126 | 24/32 | 22.5 | 24 | 21.5 | 117 | 20-φ5 | 68 | 8-M10 | 50 | 8-M10 | 2.32 |

| CSF(G)-50 | 157 | 32/40 | 30 | 31 | 28 | 147 | 16-φ5.5 | 84 | 8-M14 | 60 | 8-M14 | 4.64 |

| CSF(G)-65 | 210 | 44/52 | 37 | 39 | 35 | 198 | 20-φ6.5 | 110 | 8-M16 | 80 | 8-M16 | 9.85 |

50% thinner than traditional bearings, freeing up wiring space inside joints

Precision attenuation <5% after 2 million start-stop tests

Solid lubricant service life ≥20,000 hours

Compatible with mainstream harmonic reducers such as Harmonic Drive, Shimpo, and Lvde

Industrial robots: Collaborative robot joints (≤10kg load), SCARA robotic arm rotation units

Precision transmission: Surgical robot wrist mechanisms, satellite antenna steering mechanisms

Semiconductor equipment: Wafer handling robot θ-axis, lithography machine focus and leveling modules

New energy equipment: Fuel cell stacking robotic arms, photovoltaic panel stringer turntables

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.